Ninco Mercedes Upgrade

By Larry Shephard

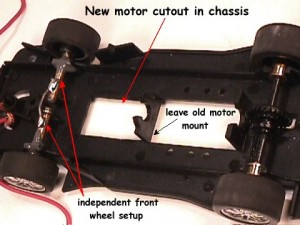

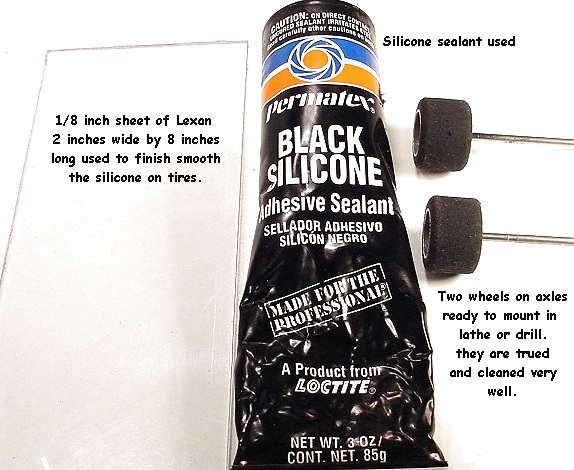

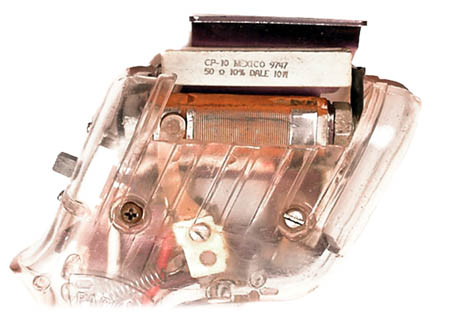

When I got my Ninco Mercedes CLK I thought, “Hey, this looks great, now what will it do on the track?” Big disappointment. It struggled down the straights and flipped in the corners. I thought some tuning was needed. So I slipped on some silicones for a bit of help but the handling and speed was still not there. It had a Fly magnet but it was not in the right place being too far forward. The big problem was being able to put it in the right place because of the big inline NC-2 motor. I played around with it some more and made the front wheels independent of each other. That helped a bit more but the Flys were zipping by me on the track like I was standing still. It was still slow on the straights, so it got relegated to the display cabinet.

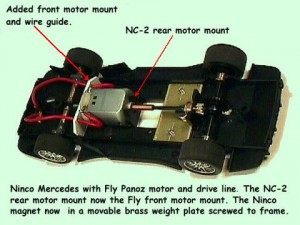

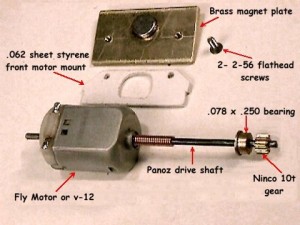

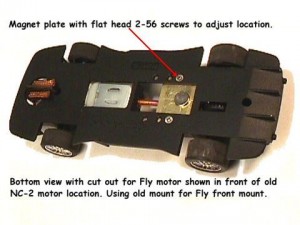

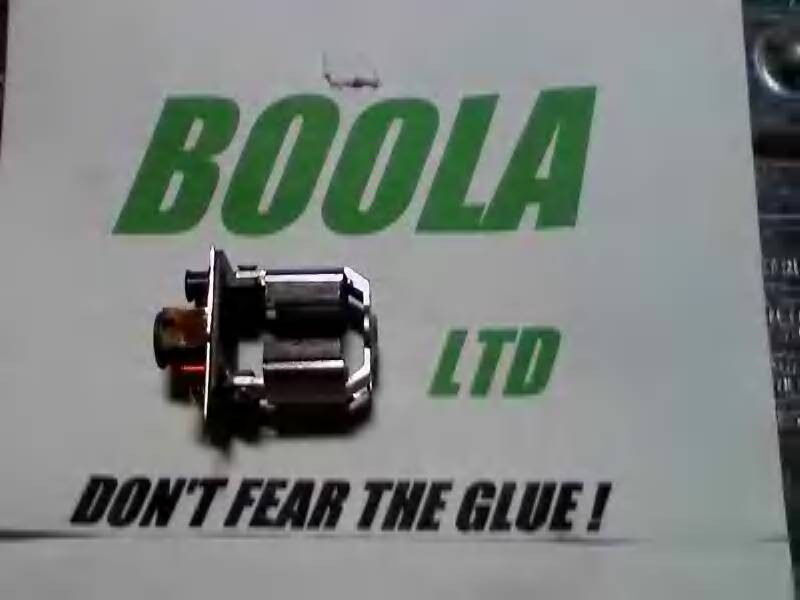

The other day I was looking at it and had an idea. Since the NC-2 was a big part of the trouble, let’s get rid of it. I could have put a Cheetah or Fox in it without too much trouble but they would have overpowered it on the track we run on. So I looked at the Panoz I had there and saw the possibility of that setup working. I got another Fly motor and ordered a Panoz drive shaft and flex piece to go with it. Now I had to do some fitting. The 10 tooth Ninco gear would stay to fit ok with present rear gearing. I used a Mura .078 x .250 arm shaft bearing in the rear motor mount to hold the rear of the drive shaft. I cut out in front of the old NC-2 rear mount enough to slip in the fly motor and fabbed up a simple cross brace type, front motor mount for the Fly motor. It was CYAed into the frame. It was shaped to fit the front of the fly motor so it would not let the motor rotate out of position. The flex part of the drive shaft was slipped on the back side of the fly motor and the drive shaft was shortened about 3/8 inch to fit. I epoxied the rear drive shaft bearing in place and it all meshed neatly. The drive shaft end of the Fly motor slipped right in the old Ninco rear chassis bearing I kept in place.

Now I could mount the Ninco/Fly magnet right in front of the rear drive shaft mount and it should work. I needed to mount the magnet in something, to hold it from hitting the drive shaft. So I used a .062 thick by 1.0 inch wide by 1/3/8 inch long piece of brass sheet with a hole taper reamed to press the magnet in and to be able to move it up and down in relation to the track for adjustment of traction. I drilled and tapped the brass plate for 2/56 flat head screws so the brass plate could be moved back and forth in the chassis for tuning. The last test of the car and setup was excellent as it would now keep up with the other stock Fly cars on the straights and in the corners blow their doors off. Very much more fun to drive and it lives up to the Mercedes CLK image. Now when the V-12 arrives look out.

A lot of work you say to keep up with the Flys. I suppose, but not many here run the Ninco cars except for the F-1s and I wanted to show some Fly drivers some tail feathers which it does now. I didn’t buy it for the display shelf so it had to perform better. The original body fits right back on the chassis with no problems so it looks like the car is in original shape. Great sleeper against the unsuspecting. I know some think this sounds like the wrong thing to do to a collector car. But I don’t. If you don’t want to, that’s fine. Oh, yes, with out the magnet in the car, the extra weight of the motor up front and the brass plate still makes it a much better handing car for non magnet races.

Larry Shephard ToyTech – Micro Tech